The leader line is sloped and ends with an arrow that must touch the parting line. The reference line and8 the identification line the reference and identification lines are drawn parallel to the bottom edge of the drawing. The identification line (dashed line) can be drawn above or below the line of reference (solid line). You can opt for https://www.metalworkmasters.com/welding/types-of-welding-symbols/ and their details.

The solid line represents the visible edge of the part and the dashed line dotted line is the hidden edge. The weld symbol the different categories of joints are characterized by a symbol recalling the shape of the welding performed. Please note, the symbol does not provide information on the welding process used. On the next page, you will find a table showing the welding symbols as well as the simplified representations. Determine their designation:

The Right Choice

Additional symbols they can complement elementary symbols to characterize the shape of the surface outer weld. The table below gives you the type of weld, whether it is flat, concave or convex. This symbol is to be added to the elementary symbol.

The dimension for the cross section is to the left of the symbol. The dimensions for the longitudinal dimensions are to the right of the symbol. The absence indication after the symbol indicates that the weld is continuous over the entire length of the welded elements. Case of fillet welds: There are two methods to define the section of the bead:

- For the bead throat, we place the letter “a” in front of the value of the bead throat.

- For the value on the side of the bead, we place the letter “z” in front of the value on the side of the bead

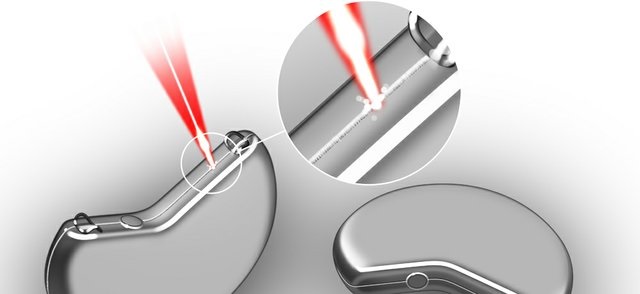

It is essential to take into account the welding position, the weld pool being always drawn downwards for reasons of the law of gravity. In orbital welding, the electrode makes a complete turn around the tube therefore all positions must be considered.

In orbital welding, we work mainly in butt (BW) mode, that is to say in tube-tube. This welding position can often represent up to 80% of welds. On the other hand, we also meet tube-plate type welds, especially in the context of heat exchangers. These welds are often easily performed with the appropriate equipment. But when it comes to fillet welds (FW), more in-depth knowledge is needed.

What are the different welding positions?

The welding positions are defined by standard EN ISO 6947: 2019. The main positions are defined by letters. Here it is the position of the electrode which turns around the tube.

Symbolization Of Welding Positions:

- PA: flat

- PB: flat angle

- PC: cornice

- PD: angled to the ceiling

- PE: on the ceiling

- PF: vertical rising

- PG: vertical descending

Apart from this configuration, it is also necessary to take into account the arrangement of the parts to be welded. In orbital welding we often find the PK position for tube to tube welding or tube to plate welding.

!

Comments